metal-organic framework compounds (mofs) have broad application prospects, and has mass production and customization capabilities

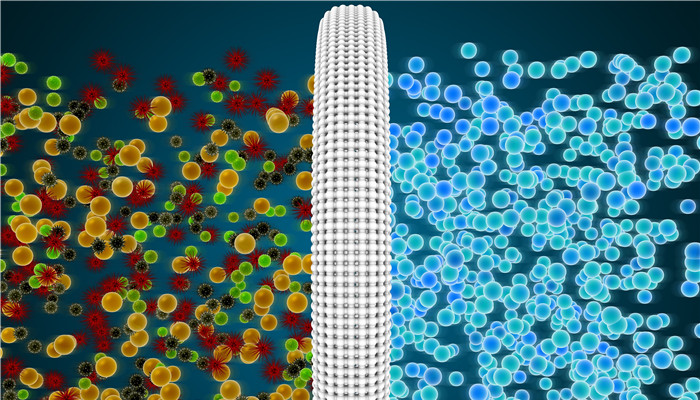

mofs have the characteristics of nano-scale pores, large surface area, many metal sites, and high carbon fixation ability. they have broad application prospects in the fields of air dehumidification, greenhouse gas adsorption, gas storage, molecular separation, hydrogen storage, catalysis, and drug sustained release. metal-organic frameworks (mofs) are a type of crystalline porous material with a periodic network structure formed by the self-assembly of inorganic metal ions or clusters and organic ligands through coordination bonds.

according to different component units, mofs can be divided into four types: reticular metal and organic framework materials (irmofs), zeolite-like imidazole framework materials (zifs), levasier framework materials (mils), and porous/channel framework materials (pcns). categories. mofs are currently one of the focuses of research and development in the field of scientific research. as research continues to deepen, the types of new mofs materials continue to increase. currently, more than 20,000 mofs materials have been developed.

according to the “2023-2027 china metal organic framework compounds (mofs) market monitoring and future development prospects research report》shows that mofs are superior to traditional porous materials in terms of specific surface area, porosity, designability, etc. with the expansion of application fields and the increase in types, the size of the mofs market continues to expand. in 2022, the global mofs market size will reach about 2.35 billion yuan. , it is expected that this market size will reach more than 8.50 billion yuan in 2028.

based on its broad application prospects, the number of mofs-related companies around the world continues to increase, including , tci, strem chemicals, bayer of germany, etc. overall, the global mofs market is mainly concentrated in north america. there is a high level of enthusiasm for mofs research around the world, and relevant research institutions in my country include the chinese academy of sciences, beijing institute of technology, huazhong university of science and technology, and university of science and technology of china. my country’s mofs material application research is weak, and there is still a gap compared with the international advanced level. among them, carbonyu new materials is the only domestic company that can achieve mass production levels above ton levels.

is the world’s largest manufacturer of mofs and the first company in the world to successfully achieve commercial-scale production of mofs. its annual output can reach hundreds of tons. it also has the ability to customize the production of mofs. has cooperated with svante technologies inc. to complete the first mofs material project. in this project, the mofs materials produced by will be used as solid adsorbents for carbon capture projects.

with the continuous deepening of research, mofs preparation methods are increasingly abundant, including hydrothermal synthesis, microwave synthesis, electrochemical deposition, template method, liquid diffusion method, spray drying, mechanical ball milling, etc. different preparation methods have their own advantages. shortcoming.

industry analysts said that as new porous materials, mofs have shown outstanding performance in hydrogen storage, catalysis, adsorption, medical treatment, gas separation and other fields. broad application prospects. with technological breakthroughs and in-depth research, the future development prospects of the mofs industry are broad. however, at present, the development of the mofs industry still faces limitations such as high production costs, low single-time output of materials, and few mass production companies. opportunities and challenges for future industry development will coexist.

微信扫一扫打赏

微信扫一扫打赏