The size of the grinding slurry market continues to grow, and the industry still has considerable room for improvement.

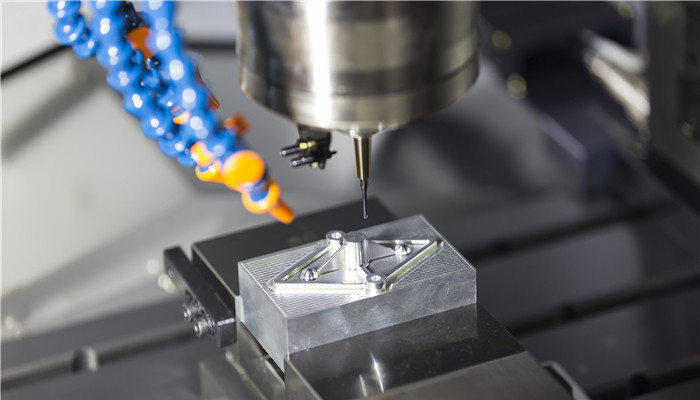

Slurry, also known as suspension, is a non-uniform and heterogeneous mixture. It is mainly used to remove the roughness and deep flaws on the surface of the workpiece, making the surface smoother, while improving the grinding efficiency and reducing the wear and tear of the abrasive tool. wear and tear. There are various types of grinding fluids. According to different abrasives, they can be divided into silica grinding fluid, diamond grinding fluid, cerium oxide grinding fluid, etc. Diamond grinding fluid can be divided into single crystal diamond grinding fluid, detonation nano diamond grinding fluid, etc.

The upstream of the grinding fluid industry chain is the supply of materials such as diamond, silica, thickeners, and surfactants; the midstream is the production and production of products; the downstream is mainly used in the grinding process during semiconductor processing.

According to the “2023-2027 Grinding Fluid Industry In-depth Market Research and Investment Strategy Suggestion Report” released by the Industrial Research Center, with the my country’s economy continues to develop, the scale of high-end manufacturing continues to expand, and the semiconductor industry is developing well driven by national policies and market demand, driving the growth of the polishing slurry market. In 2018, the market size of my country’s grinding fluid market was approximately 1.6 billion yuan. In 2022, the market size will exceed 2.2 billion yuan, with a compound annual growth rate of more than 8% from 2018 to 2022.

In recent years, the country has issued a number of policies to encourage and support the development of the semiconductor industry. In January 2023, six departments including the Ministry of Industry and Information Technology jointly issued the “Guiding Opinions on Promoting the Development of the Energy Electronics Industry”, proposing to study the basics of miniaturization, high performance, high efficiency, and high reliability of power semiconductors, sensing devices, and optoelectronic devices. Electronic components, special equipment, and advanced technology. In March 2022, the National Development and Reform Commission issued the “14th Five-Year Plan for Digital Economy Development”, proposing to focus on improving the supply level of basic software and hardware, core electronic components, key basic materials and production equipment, and strengthening the self-sufficiency of key products. As a key basic material in the semiconductor industry, polishing fluid has a good development environment.

After a period of development, my country’s abrasive slurry industry has continued to advance in production technology, gradually breaking foreign monopolies, continuously accelerating the localization of the market, and gradually reducing its dependence on imported products. However, due to limitations in talent, technology, etc., the overall production technology is not as advanced as foreign countries. There is still a certain gap, and the industry still has a lot of room for improvement. In 2022, the domestic grinding fluid market share will be close to 60%, and the imported grinding fluid market share will be approximately 40%. Domestic grinding slurry manufacturers mainly include Dongguan Chuangli Grinding Technology Co., Ltd., Shanghai Xinyang Semiconductor Materials Co., Ltd., Shenzhen Zhenhongxing Grinding Technology Co., Ltd., Beijing Guorui Sheng Technology Co., Ltd., etc.

Industry analysts said that with the continuous improvement of my country’s scientific and technological development level and the continuous development of the semiconductor industry, the market demand for grinding fluids will continue to grow. The industry has good development prospects. In the context of the continuous updating of semiconductor production technology and the acceleration of product upgrading, the market’s requirements for the quality and performance of polishing fluids are also constantly increasing. Domestic production companies need to continuously improve production technology, develop new technologies and new products to meet the continuous needs of the market. Enhanced diversification and personalized needs.

微信扫一扫打赏

微信扫一扫打赏