Electrolytic copper foil has a broad consumer market and low industry concentration

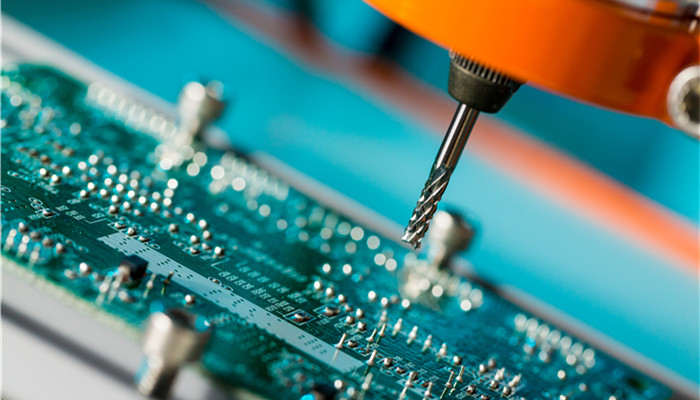

Electrolytic copper foil refers to metal copper foil produced by electrolysis using copper as the main raw material. There are various types of electrolytic copper foil, which can be divided into ultra-thin copper foil, thin copper foil, conventional copper foil, thick copper foil, etc. according to different thicknesses; according to different surface conditions, they can be divided into single-sided rough copper foil, double-sided rough copper foil, double-sided rough copper foil, etc. Surface gloss copper foil, ultra-low profile copper foil, etc.; according to different production processes, it can be divided into lithium battery copper foil, rolled copper foil, electronic circuit copper foil, etc.

The upstream of the electrolytic copper foil industry chain is the supply of copper, sulfuric acid and other materials; the midstream is the production of various products; the downstream is widely used in consumer electronics, new energy vehicles, industrial equipment and other fields.

From the perspective of product segmentation, my country’s lithium battery copper foil production will account for more than 51% in 2022, ranking first, and electronic circuit copper foil production will account for more than 45%, ranking second.

According to the “China Electrolytic Copper Foil Industry Market In-depth Research and Development Prospects Forecast Report 2023-2028” released by the Industrial Research Center, Electrolytic copper foil is one of the important materials for the manufacturing of copper-clad laminates, lithium batteries and printed circuit boards. In recent years, with the continuous development of my country’s economy, the scale of high-end manufacturing has continued to expand. Driven by downstream demand, lithium batteries, printed circuit boards and other industries have continued to expand, bringing a broad consumer market to electrolytic copper foil. In 2022, my country’s lithium battery output will exceed 23 billion units, a year-on-year increase of approximately 3%.

With the continuous development of the industry and the continuous advancement of production technology, the output of electrolytic copper foil in my country continues to grow. In 2022, my country’s electrolytic copper foil output will exceed 780,000 tons, a year-on-year increase of approximately 23%. At the same time, the sales volume of electrolytic copper foil maintained a rapid growth trend, and the industry prosperity was good. In 2022, China’s electrolytic copper foil sales will exceed 780,000 tons, a year-on-year increase of approximately 23%.

In the context of the accelerated upgrading of consumer electronics products, the continuous advancement of lithium battery production processes, and the continuous development of emerging industries such as new energy, the market’s requirements for the quality, appearance, performance, etc. of electrolytic copper foil continue to grow, pushing the industry towards thinner, lighter, and lower Contour, high ductility and other directions.

The electrolytic copper foil industry has a low threshold, but there are many production processes and product quality is difficult to control. At present, there are a large number of electrolytic copper foil manufacturers in my country, and the industry competition is fierce. It is difficult for a single brand to occupy a large market share, and the industry concentration is low. After a period of development, my country’s electrolytic copper foil industry has made great progress in its overall production level. However, there is still a certain gap compared with the international advanced level, and the industry still has a lot of room for development. Domestic electrolytic copper foil manufacturers include Kingboard Copper Foil Group Co., Ltd., Shenzhen Longdian Huaxin Holding Group Co., Ltd., Changchun Chemical (Jiangsu) Co., Ltd., Jiujiang Defu Technology Co., Ltd., etc.

Industry analysts said that with the continuous development of my country’s new energy, electronic information and other industries, the market demand for electrolytic copper foil will continue to grow. The industry has good development prospects. As competition in the industry continues to intensify, manufacturers with poor product quality and backward production capacity will gradually withdraw from the market, and the concentration of the electrolytic copper foil industry will further increase. Domestic electrolytic copper foil manufacturers need to continuously improve their independent innovation capabilities, optimize product performance, and enhance their core competitiveness.

微信扫一扫打赏

微信扫一扫打赏