Low shrinkage polypropylene has great room for development in the automotive field and China’s production capacity is expected to increase

Low shrinkage polypropylene is a type of high-end polypropylene product. Compared with ordinary polypropylene, its shrinkage rate is greatly reduced and its dimensional stability is high.

According to the “China Low Shrinkage Polypropylene Industry Market In-depth Research and Development Prospects Forecast Report 2023-2028” released by the Industrial Research Center It shows that polypropylene (PP), one of the four general-purpose plastics, has the advantages of light weight, high mechanical strength, good toughness, wear resistance, heat resistance, corrosion resistance, electrical insulation, easy processing, etc., and can be used in a wide range of downstream applications. However, polypropylene also has the disadvantage of high shrinkage, and the processed products are prone to poor dimensional stability, making it difficult to manufacture precision parts. Therefore, low shrinkage polypropylene has received attention.

The shrinkage rate of polypropylene is mainly controlled by the molecular structure and crystal structure. The preparation process of low shrinkage polypropylene mainly includes: using fiber reinforcement methods, such as glass fiber, basalt fiber, etc. for modification; using mineral material filling methods, such as using talc powder , calcium carbonate (CaCO3), etc. are modified; fiber reinforcement + mineral material filling method is used; compounded with other polymers, such as polystyrene (PS) with low shrinkage but poor toughness, so that the performance of the two complements each other. .

In comparison, the shrinkage rate of low-shrinkage polypropylene made by fiber reinforcement method and mineral filling method is reduced in the horizontal flow direction, but the shrinkage rate in the vertical flow direction does not change much; fiber reinforcement + mineral filling method, high molecular polymer The low shrinkage polypropylene made by the composite method has better comprehensive properties.

my country is a major producer of polypropylene, and polypropylene production capacity continues to expand. As of June 2023, my country’s polypropylene production capacity exceeds 36 million tons. Since 2020, a large amount of polypropylene production capacity in my country has entered production, but the market demand for polypropylene has been difficult to grow significantly, resulting in overcapacity of polypropylene in my country and increasing pressure on the supply side. Overall, my country’s polypropylene production capacity is mainly concentrated in the field of low-end general-purpose products. High-end polypropylene production capacity accounts for a small proportion, and most product demand is highly dependent on external sources. Against this background, the structure of my country’s polypropylene industry is in urgent need of adjustment. As one of the high-end polypropylene products, low-shrinkage polypropylene is expected to increase its production capacity.

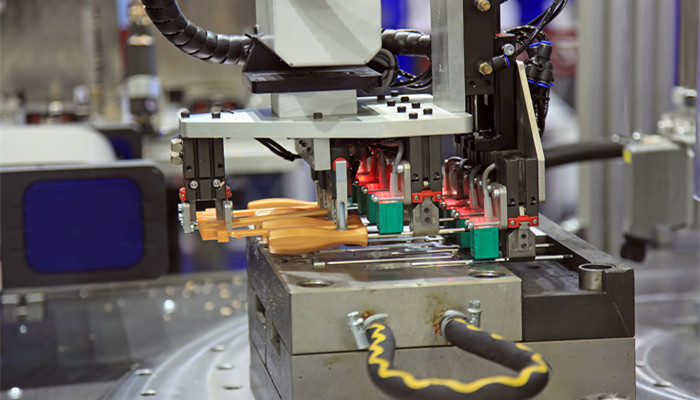

Industry analysts said that low shrinkage polypropylene is mainly used in the automotive field and can be used to make automotive interior and exterior decorations, such as bumpers, Door sills, side skirts, etc. can meet the needs of use in high and low temperature environments and can be used as an alternative to ABS. ABS is an important material for manufacturing automobile interior and exterior decorations, but it is subject to light and oxidation, and can easily turn yellow and brittle after long-term exposure, affecting safety and aesthetics. In 2022, my country’s passenger car interior and exterior decoration market will exceed 160 billion yuan, and low-shrinkage polypropylene has broad room for development.

Globally, the main low-shrinkage polypropylene manufacturers include Korea Petrochemical, Sumitomo Chemical, LyondellBasell, Borealis, etc.

微信扫一扫打赏

微信扫一扫打赏