Aluminum etching liquid is mainly used in LCD panel manufacturing scenarios. There are only a small number of companies in my country’s market.

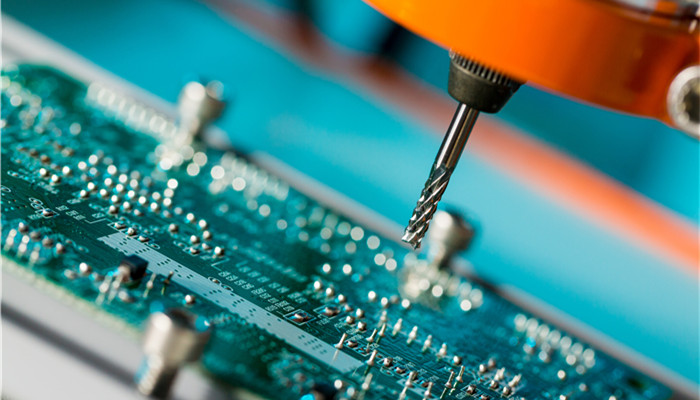

Aluminum etching solution refers to a liquid material that uses acid corrosives to etch the surface of aluminum and aluminum alloy metals. The main ingredients include phosphoric acid, acetic acid, water, etc. Aluminum etching liquid has the advantages of strong corrosive ability, fast etching speed, and high saturated solubility of aluminum. It can be widely used in the surface treatment process of printed circuit boards, electronic components, instrument components and other materials, and the market demand is huge.

Etching refers to a technology that uses chemical reactions or physical impacts to remove part of the material. It has now become one of the important links in the semiconductor manufacturing process and micro-nano manufacturing process. The quality of its process technology has a significant impact on the accuracy and reliability of the device. direct impact. Aluminum etching liquid is one of the important materials for the etching process. Its working principle is to destroy the oxide film on the surface of aluminum metal through active ions in the aluminum etching liquid. As the corrosion continues, pitting corrosion is formed, which is then flushed by high-pressure pump. The process of uniformly etching to achieve the purpose of etching.

As thin film materials, aluminum and aluminum alloys have the advantages of low cost, low resistance, and good bonding with other film layers. Therefore, metallic aluminum and its alloy thin film materials can be widely used in panel manufacturing scenarios in the field of liquid crystal displays. As an important material for realizing the aluminum metal etching process, aluminum etching liquid has the same application fields as the application fields of metallic aluminum and its alloy thin film materials.

According to the “2023-2028 Aluminum Etching Liquid Industry Market In-depth Research and Investment Prospects Forecast Analysis Report” released by the Industrial Research Center, The domestic LCD panel market size will exceed 28 billion yuan in 2022. Currently, against the background of the continuous expansion of the domestic LCD panel market scale, the demand for aluminum etching solutions continues to increase, and the industry development prospects are good. Among them, aluminum-molybdenum etching solution is currently the mainstream product in the etching solution market for display panels.

At present, the main aluminum etching solution manufacturers in my country include Shenzhen Xinzhoubang Technology, Fujian Tianfu Electronic Materials, Fujian Del Technology, Jiangyin Runma Electronic Materials, Jiangyin Jianghua Microelectronic Materials, Jiangsu Zhongde Electronic Materials Technology, and Hubei Xingfu Electronic Materials. , Yancheng Weixin Electronics, TCL CSOT Technology, Hubei Xingfu Electronic Materials, Hangzhou Glinda Electronic Materials, etc.

Industry analysts said that aluminum etching liquid is one of the important materials required in the etching process of semiconductor devices. Especially the display panel manufacturing scene in liquid crystal display devices. Under the current background of rapid development of the domestic LCD panel market, the demand for aluminum etching solutions continues to increase, and the industry shows good development prospects. However, aluminum etching liquid, as an important type of wet electronic chemicals, has high technical barriers. At present, the number of companies in this field in my country is still relatively small, and the production capacity is still relatively low. In the future, local companies will need to continue to increase technology research and development efforts. , to promote the continuous improvement of domestic market supply capacity.

微信扫一扫打赏

微信扫一扫打赏