Microcrystalline silicon film (nanocrystalline silicon film) can be used to manufacture HJT batteries. There are few market participants in my country

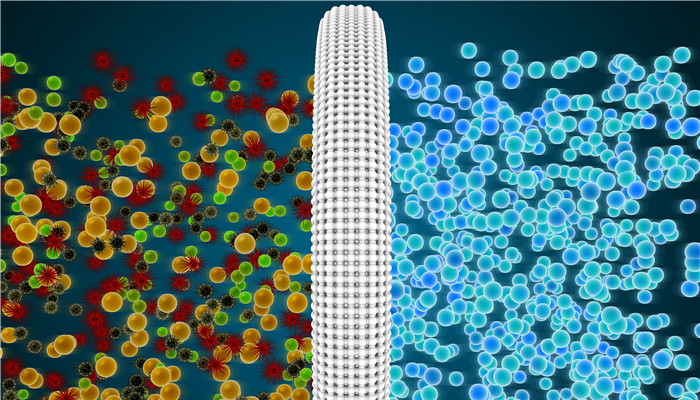

Microcrystalline silicon film, also known as nanocrystalline silicon film, refers to a mixed crystalline silicon film between amorphous silicon and single crystal silicon, consisting of microcrystalline grains, a small number of microcavities, grain boundaries and amorphous parent material. Compared with traditional amorphous silicon films, microcrystalline silicon films have the advantages of higher doping efficiency, good conductivity, good thermal resistance, good photoelectric properties, and high light absorption coefficient. They are widely used in optoelectronics such as display devices, laser devices, and solar cells. Wide range of applications.

Microcrystalline silicon thin film preparation methods include dipping, sputtering and chemical vapor deposition (CVD). The chemical vapor deposition method can be subdivided into hot wire chemical vapor deposition (HWCVD), radio frequency plasma chemical vapor deposition (PECVD), etc. The radio frequency plasma chemical vapor deposition method has the advantages of fast deposition rate, good finished product quality, and low film forming temperature, but its output is low and the production cost is high; the hot wire chemical vapor deposition method has the advantages of low production cost and low equipment requirements. , suitable for continuous production.

Metallic silicon is the main raw material of microcrystalline silicon film. Metallic silicon is also called industrial silicon. Silicon element is its main component and is widely used in the photovoltaic and semiconductor fields. In recent years, with the growth of market demand, my country’s silicon metal production has further increased. According to statistics from the Raw Materials Industry Department of the Ministry of Industry and Information Technology, my country’s silicon metal production reached 1.436 million tons in the first half of 2022, a year-on-year increase of 26.9%. Yunnan, Xinjiang and Sichuan are the main silicon metal producing areas in my country. The sufficient supply of raw materials has laid a good foundation for the development of my country’s microcrystalline silicon film industry.

According to the “2023-2028 Microcrystalline Silicon Film (Nanocrystalline Silicon Film) Industry Market In-depth Research and Investment Prospect Forecast Analysis Report released by the Industrial Research Center 》shows that the solar cell field is the largest demand end for microcrystalline silicon thin films, which can be used to manufacture crystalline silicon heterojunction solar cells (HJT cells). HJT cells have the advantages of strong resistance to light decay, low operation and maintenance pressure, double-sided passivation, and strong adaptability. With technological advancement in the future, they are expected to become the mainstream product in the photovoltaic N-type battery market. Microcrystalline silicon thin film has excellent performance. As the prosperity of the HJT battery industry increases, its market demand will become increasingly strong.

The technical barriers to the microcrystalline silicon thin film industry are relatively high, and there are very few companies in my country with large-scale production capabilities. Jinshi Energy, Huasheng New Energy, Risen Energy, Tongwei Technology, etc. are the main players in my country’s microcrystalline silicon film market. Huasheng New Energy focuses on the R&D and production of HJT cells and has a number of invention patents for microcrystalline silicon thin film solar cells.

Industry analysts said that as an important component of solar cells, microcrystalline silicon thin films have excellent performance and broad market prospects. my country is a major producer of metallic silicon, and its raw material advantages provide favorable conditions for the development of the microcrystalline silicon thin film industry. In recent years, Chinese companies have continued to increase research on microcrystalline silicon thin film preparation methods. It is expected that the development speed of my country’s microcrystalline silicon thin film industry will accelerate in the future.

微信扫一扫打赏

微信扫一扫打赏