Background and overview[1]

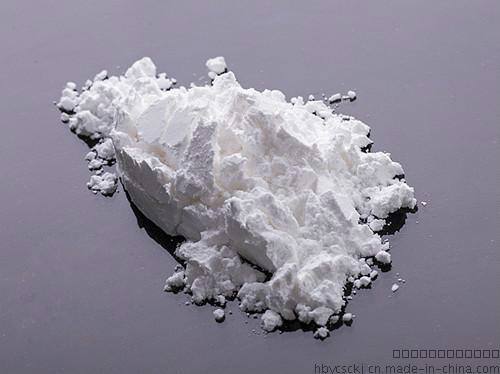

Hydroquinone monomethyl ether (HQMME) is a fine chemical product with a wide range of uses. The traditional synthesis method using hydroquinone and dimethyl sulfate as raw materials has many shortcomings. For example, dimethyl sulfate is expensive and highly toxic, generates a large amount of Na2SO4 by-products that are difficult to handle and discharge, and is accompanied by hydroquinone dimethyl ether, causing product separation. Difficulties in purification, etc. In recent years, there have been reports in the literature that HQMME was synthesized through intermolecular dehydration and etherification using hydroquinone (HQ) and methanol as raw materials under the action of an acid catalyst with oxidizing ability.

Application[2-5]

Hydroquinone monomethyl ether is an efficient polymerization inhibitor for unsaturated polyester resins, methyl methacrylate, acrylonitrile, vinyl acetate, etc.; it is a stabilizer for polymers such as polyvinyl chloride and polymethacrylic acid. It can also be used as an antioxidant and pharmaceutical intermediate. When made into an ointment, it can be used as a bleaching agent, decolorizing agent, and infrared Z absorber. Examples of its application are as follows:

1) Prepare a light-curing acrylic polyurethane coating. The coating is composed of rosin epoxy acrylic resin (prepared from the esterification reaction of (meth)acrylic acid and rosin glycidyl ester and rosin glycidol), isophorone di Isocyanate, tetraethylene diacrylate (dilute solution), hydroquinone monomethyl ether (polymerization inhibitor), 2-hydroxyethyl acrylate, pentaerythritol triacrylate, stannous octoate, hydroquinone monomethyl ether (relative total added amount ) composition. The coating film has excellent flexibility, abrasion resistance, and chemical resistance. Construction using conventional coating methods. In the industrial field, in addition to being suitable for coating wood, it is also widely used in printing ink, paper varnish, solder protective layer, etc.

2) Prepare an art paint with the following raw materials in parts by weight: 100 parts of alkyd resin; 35-45 parts of castor oil; 15-25 parts of diatomaceous earth; 30-40 parts of xylene; flax 25-45 parts of seed oil; 1-10 parts of hydroquinone monomethyl ether; 5-15 parts of organic bentonite; 15-35 parts of stannous octoate; 20-30 parts of pigments and fillers; 5-25 parts of tetraethylene diacrylate ; 15-35 parts of cobalt naphthenate; 10-30 parts of trimethylolpropane triacrylate; 30-40 parts of toughening agent; 10-30 parts of hexylene glycol diacrylate; 10-20 parts of manganese naphthenate ; 15-25 parts of benzotriazole; uniform coating color, viscosity 80-120s; fineness 25-35μm, hiding power 90-100g/cm2; surface drying 0.1-0.3h, solid drying 0.5-1.5h; water resistance 5 -15d, can be widely produced and continue to replace existing materials.

3) Prepare a kind of imitation porcelain multi-colored paint. The raw materials are proportioned in parts by weight as follows: 100 parts of polyvinyl alcohol; 15-25 parts of white cement; 30-40 parts of formaldehyde; 35-45 parts of vinyl dichloride; 25-45 parts of urea; 20-40 parts of sodium bicarbonate; 80-90 parts of deionized water; 5-15 parts of hexahydroxymethylmelamine; 10-20 parts of pigment; 15-35 parts of allyl alcohol; 25 parts of glass powder -35 parts; 10-20 parts of trihydroxypropane triacrylate; 8-10 parts of plasticizer; 10-30 parts of benzoin ether; 20-30 parts of tung oil; 5-25 parts of hydroquinone monomethyl ether; the coating is resistant to scrubbing 2000-3000 times, no blistering or wrinkles after soaking in water for 30-50 days; surface drying for 0.5-1.5 hours, hard drying for 18-20 hours, no powder or peeling off after soaking in saturated calcium hydroxide solution for 10-30 days; The coating film is brightly colored and has 100% adhesion. It can be widely produced and continuously replace existing materials.

4) Prepare a modified fluorenyl epoxy resin composite material with enhanced toughness, which is characterized in that it is made from the following raw materials in parts by weight: fluorenyl epoxy resin 50-55, carboxyl-terminated liquid nitrile Rubber 8-12, diatomaceous earth 1-3, shea butter 5-8, urea 1-2, silicone 3-4, antioxidant DSTP1.2-2.5, titanate coupling agent TC-1300.6- 1.3. Linseed oil fatty acid 7-11, dipropylene glycol butyl ether 8-12, pentaerythritol 4-7, hydroquinone monomethyl ether 5-8, chromic anhydride 2-4, ethylene glycol dimethacrylate 12-15, three Ethanolamine 6-9, additives 3-6; the fluorene-based epoxy resin composite material of the present invention has high toughness, good wear resistance, is not easy to delaminate, and has strong adaptability, so it is prepared based on the modified fluorene-based epoxy resin. Coatings and paints have the advantages of high hardness, good toughness, fast drying speed, good impact resistance and excellent anti-corrosion and anti-cracking properties. In addition, the present invention optimizes the production formula and synthesis process, reducing costs. Compared with the existing technology, It has good economic and social benefits.

Main reference materials

[1] Research on the catalytic synthesis of hydroquinone monomethyl ether by solid acid

[2] CN200810159383.1 A light-curing acrylic polyurethane coating and its preparation method

[3] CN201410437513.9 An art paint

[4] CN201410437572.6 A kind of imitation porcelain multi-colored coating

[5] CN201410600321.5 A modified fluorene-based epoxy resin composite material with enhanced toughness and its production method

微信扫一扫打赏

微信扫一扫打赏