my country’s ultrapure water (UPW) consumption is huge, and the localization level of electronic-grade UPW equipment needs to be improved.

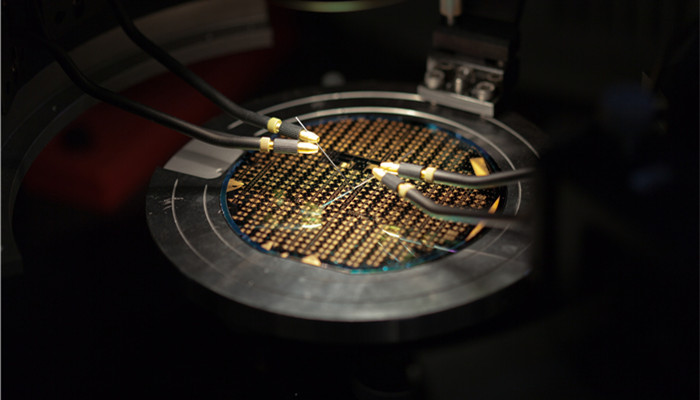

Ultrapure water, also known as UPW, refers to water with a resistivity of 18MΩ*cm (25℃). Ultrapure water is water produced for the purpose of developing ultrapure materials. The water contains almost no impurities except hydrogen ions and hydroxide ions. Ultrapure water has a wide range of applications, including electronics, medical treatment, scientific experiments, precision instruments, petroleum, chemical industry, electroplating and coating, reagent dilution, photovoltaic cells, nuclear industry and other fields. Among them, electronics is the main application field of ultrapure water. In this field, ultrapure water is mainly used in cleaning silicon wafers and semiconductor materials, configuring electroplating solutions, cooling equipment, silicon wafer oxidation and other scenarios. It has now become a factor that affects the quality of electronic components and products. One of the key materials for yield.

More than 80% of the processes in the integrated circuit production process require the use of high-purity water, and its market demand is relatively broad. Currently, driven by the rapid development of the global electronic information industry, the continuous expansion of the integrated circuit market has driven the demand for ultrapure water to continue to increase. According to the “China Ultrapure Water Industry Market Supply and Demand Status and Development Trend Forecast Report 2023-2028” released by the Industrial Research Center, The global ultrapure water market will reach US$5.58 billion in 2022, a year-on-year growth of 8.6%. From the perspective of regional distribution, China is the world’s largest consumer market for ultrapure water. At the same time, as the global semiconductor industry moves to China, the scale of my country’s ultrapure water consumption is expanding as a proportion of the world’s total.

The ultrapure water manufacturing process is difficult and needs to be prepared through three stages: preliminary adsorption filtration, reverse osmosis purification and resin ion exchange. The main processes include mechanical filtration, activated carbon filtration, reverse osmosis membrane filtration, ultraviolet digestion, ion exchange resin, 0.2 μm membrane filtration, etc. At present, ultrapure water preparation mainly relies on ultrapure water equipment systems, including pretreatment systems, reverse osmosis devices, post-treatment systems, cleaning systems and electrical control systems.

There are many domestic ultrapure water equipment companies, mainly including Lanxiao Technology, Jiazhou Purification Equipment, Tianyu Water Treatment Engineering, Hanzhong Alliance Environmental Technology, Xinshengtai Water Treatment and Environmental Protection, Aike Environmental Protection Equipment, Chunhan Environmental Protection Equipment, Laitelai Dechao pure water equipment, Hennuo water treatment equipment, Veolia water treatment equipment, etc. However, domestic ultrapure water equipment is mostly low-end equipment with low processing levels and cannot produce high-end ultrapure water such as electronic grade and nuclear power grade.

Industry AnalysisPersonnel said that in recent years, driven by the rapid development of my country’s semiconductor industry, ultrapure water, as a key material that affects the quality and yield of electronic components, has continued to increase its market demand, and industry development The prospects are better. Ultrapure water preparation mainly relies on ultrapure water equipment systems. Due to technical limitations, the current production level of domestic ultrapure water equipment is still relatively low. The production of high-end ultrapure water such as electronic grade and nuclear power grade still relies on imported equipment. In the future, local production Enterprises also need to speed up technology research and development.

微信扫一扫打赏

微信扫一扫打赏