The PECVD nanofilm industry has broad development prospects and the global market presents an oligopoly competition pattern.

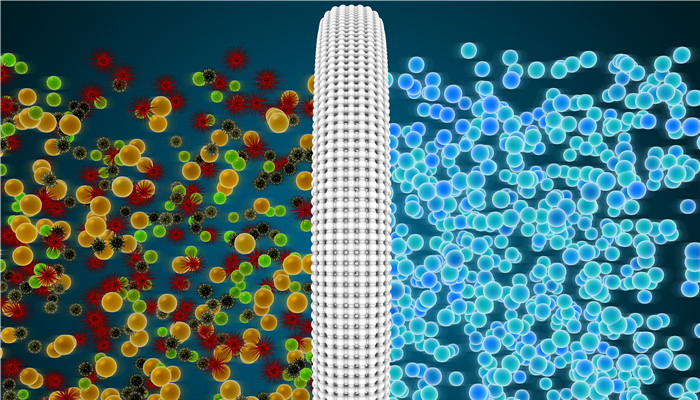

Nanofilm refers to a film composed of particles (crystals) with a size of nanometers or a film with a layer thickness of nanometers. According to different production methods, nanofilms can be divided into atmospheric pressure chemical vapor deposition (APCVD), low pressure chemical vapor deposition (LPCVD), plasma enhanced chemical vapor deposition (PECVD), atomic layer deposition (ALD) films, etc. PECVD nanofilm refers to nanofilm produced by PECVD coating technology.

According to the “China PECVD Nano Film Industry Market Monitoring and Future Development Prospects Research Report 2023-2027” released by the Industrial Research Center , PECVD nanofilm has the advantages of good waterproof performance, strong anti-corrosion performance, and excellent barrier performance. It has been widely used in consumer electronics, automotive electronics, wearable devices, optical instruments, medical equipment and other fields, and the market demand is broad.

Among them, consumer electronics is the main application field of PECVD nanofilm. In this field, PECVD nanofilm is mainly used as a protective material for internal circuit boards. Compared with the traditional protective material conformal paint, PECVD nano-film technology has lower cost, higher environmental protection, thinner film layer and better protective performance; compared with parylene coating, PECVD nano-film technology has lower cost and better protection performance. The performance is better, the film layer performance is higher, and it is applicable to a wider range of substrates.

Currently, as the superior performance of PECVD nanofilms continues to be highlighted, its penetration rate in the consumer electronics market is continuously increasing. Taking headphones as an example, the global PECVD nanofilm market for headphones will reach 2.51 billion yuan in 2022, a year-on-year increase of 11.4%. In the future, as the market penetration rate of PECVD nanofilm continues to increase, it is expected to replace conformal paint and parylin coating as the mainstream protective material in the consumer electronics market, and the market development potential is huge.

PECVD nano-film technology and financial barriers are high. Currently, the number of companies with mass production capabilities in the world is relatively small. The main companies include British P2i, American HzO, Belgian Europlasm, and Chinese Fevotel Nanotechnology, etc., and each company focuses on different areas. . Specifically, Fivotech focuses on the consumer electronics field, P2i focuses on the automotive and consumer electronics fields, HzO focuses on the automotive field, and Europlasm focuses on the medical device field. At present, the global PECVD nanofilm market presents an oligopoly competition pattern, with weak market competition.

Industry analysts said that PECVD nanofilm is a type of nanofilm material produced using advanced PECVD coating technology and has been widely used. In the fields of electronics, automobiles, industry, and medical care, in the future, as its superior performance continues to be highlighted, the application fields of PECVD nanofilms will continue to expand into high-tech fields such as new energy vehicles, photovoltaic power generation equipment, aerospace, etc., and the industry development prospects are broad. However, due to technical limitations, there are currently only a relatively small number of companies globally capable of supplying PECVD nanofilms on a large scale, and the market is less competitive. In the future, relevant companies will need to continue to break through key technologies to speed up meeting market demand and promote the rapid development of the industry.

微信扫一扫打赏

微信扫一扫打赏