Prussian blue cathode materials have outstanding advantages in high energy density, and the technology and process are still being optimized.

The overall performance of sodium-ion batteries is significantly better than that of lead-acid batteries. With its advantages of sufficient raw materials, low cost, high safety, and wide temperature adaptability, it can replace lithium-ion batteries in some application scenarios. It is expected that by 2025, my country’s sodium-ion batteries will The potential demand will reach 200GWh, and the market development space is huge. The structure of sodium-ion batteries is the same as that of lithium-ion batteries. From the perspective of cathode materials, Prussian blue compounds, layered oxides, and polyanionic compounds are the three major technical routes for cathode materials for sodium-ion batteries.

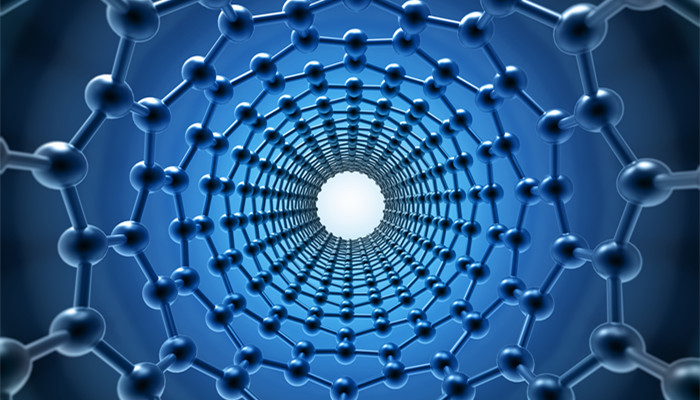

Prussian blue compounds, the chemical formula is NaxM1[M2(CN)6]y·nH2O, M1 and M2 are transition metal elements, Fe, Mn, Cu, Ni, Co, etc. can be used. Prussian blue compounds include two types: sodium-poor state and sodium-rich state. Because the sodium-rich state of Prussian blue appears white, it is also called Prussian white. Representative products of Prussian blue cathode materials include Na2Fe[Fe(CN)6], Na2Mn[Fe(CN)6], Na2Mn[Mn(CN)6], etc.

According to the “2023-2028 China Prussian Blue Cathode Materials Industry Market In-depth Research and Development Prospects Forecast Report” released by the Industrial Research Center It shows that Prussian blue cathode materials have outstanding advantages of high energy density. It is the product type with the highest energy density among the three major sodium-ion battery cathode material technology routes, reaching 120-160wh/kg; in addition, Prussian blue cathode materials also have raw material costs It has the advantages of low cost, high cost performance, high structural stability, good rate capability, and adjustable operating voltage, making it one of the ideal solutions for sodium-ion battery cathode materials.

Prussian blue cathode materials also have some shortcomings. Their cycle life is limited, and the number of charge and discharge times is only about 3,000 times. This is mainly because Prussian blue compounds are easy to absorb water, and crystal water is difficult to remove during the manufacturing process. During storage and use It is susceptible to moisture, resulting in poor chemical stability and reduced charge and discharge times. In addition, the operating temperature range of Prussian blue cathode materials is narrow, between -20 degrees and 40 degrees. These factors have restricted the industrial development of Prussian blue cathode materials.

With the continuous deepening of technical research, the technical process of Prussian blue cathode materials is continuously improved. During the manufacturing process, the crystallization water content is controlled by controlling the crystallization speed, adding additives, using inert gas protection, doping, surface coating, etc. Protect transition metals from oxidation and improve product performance. Since the three major categories of sodium-ion battery cathode materials have different advantages and disadvantages, the situation of multiple technology routes coexisting will exist for a long time in the future. With continuous technological breakthroughs, Prussian blue cathode materials have good development prospects.

Industry analysts said that in overseas markets, the main manufacturers of Prussian blue cathode materials include Natron Energy of the United States. Attracted by market prospects, the number of sodium-ion battery cathode material companies in my country continues to increase. Among them, CATL, Rongbai Technology, Sodium Innovation Energy, Starry Sodium, Midland New Materials, Colorful Chemical, etc. are participating in the Prussian blue cathode material market. At present, layered oxide cathode materials are the mainstream technology route for sodium-ion batteries. There are many mass-produced companies. The Prussian blue cathode material technology is still in the process of improvement. The number of mass-produced companies is small, and many companies are still in the strategic layout stage.

微信扫一扫打赏

微信扫一扫打赏